Kitchen & Laundry

In House Capabilities: the CNC Machine

25 Nov 2015

Brand: Haas – American, largest CNC manufacturer in western world, just entered a team into F1 for 2016

Model: VF2 Super Speed

Capabilities: 4 axis of motion simultaneously, accurate to 0.005mm, maximum spindle speed 12,000rpm

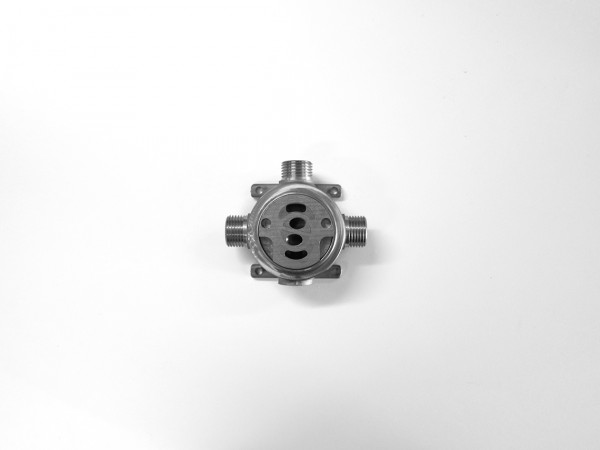

The VF2 is kept busy machining our forged brass engine bodies. From 3 different raw forgings we produce our Fusion Plus™, Fusion™, Flexidisc™, Diverter and Exposed range of shower mixers.

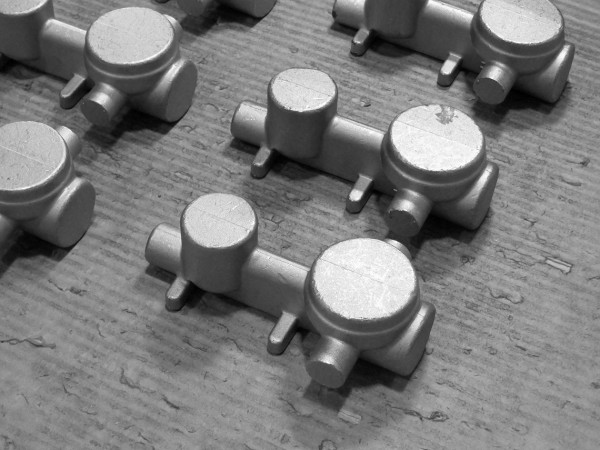

Image: forged brass engine diverter bodies prior to machining

Image: forged brass engine diverter bodies after machining in the CNC

Image: the CNC machine underway

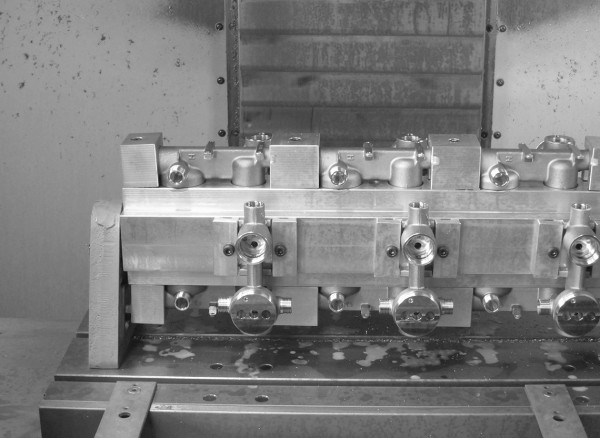

Images: machined brass bodies on the CNC jig

By using custom made jigs to hold multiple forgings at once, and combining the 4 axis motion of the CNC we can produce the finished product very accurately and efficiently. It’s a truly automated procedure, with the operator only required to load the parts into the machine and quality check the finished product. While it’s running, there’s no need for anyone to oversee the CNC.

When we’re not using it to produce our shower mixer engines, it gives Felton the ability to quickly and accurately prototype new products and designs.

Images: brass Fusion Plus prototypes machined in the CNC

We introduced the CNC at the end of 2013, with full production underway mid February 2014. Since its introduction, we have seen big gains in efficiency from machining in house:

- Reduction in lead times (we can make the engines much more rapidly)

- Increase in quality (we have much better control over the tolerances of the parts meaning better fitting product)

- Rapid response to issues (defects are picked up and addressed as soon as they happen)

- Increased ability to design and prototype new products

Any waste produced from this machine is recycled.

Written by Heather M